Categories

Throwing machine

Throwing machine

The company's main products are: En - masse conveyor, bucket elevator, screw conveyor, belt conveyor, slat conveyor, FU drag chain conveyor, crusher and all kinds of manual, electric, pneumatic gate & valves, slag silo and so on.

PRODUCT DESCRIPTION

●Throwing machine

A throwing machine is a specialized device designed to propel objects or materials through the air using mechanical force. In the conveying industry, it is used to efficiently distribute, transport, or position materials over a distance. This can include small parts like nuts and bolts, larger objects such as bricks or concrete blocks, or even bulk materials like grains and powders.

●Working process and working principle:

When the material needs to be transported to the designated position, push the ejector to the corresponding position, and then load the material into the ejector through the feeding port, and the material falls to the driving pinch pulley, which drives the drive under the action of the driving device. The pinch roller rotates, which in turn drives the throwing belt to rotate. The material falls on the throwing belt running at high speed, and the material is transported forward through the throwing belt. When it reaches the end of the conveyor belt, the material will be thrown out of the host under the action of inertia. The shell 3 is finally shot to the position where feeding is required.

By adjusting the tension of the No. 1 tensioning drum, the No. 2 tensioning drum and the driving pinch roller, the tension of the throwing belt and the throwing direction can be adjusted, and the throwing distance can be adjusted at the same time.

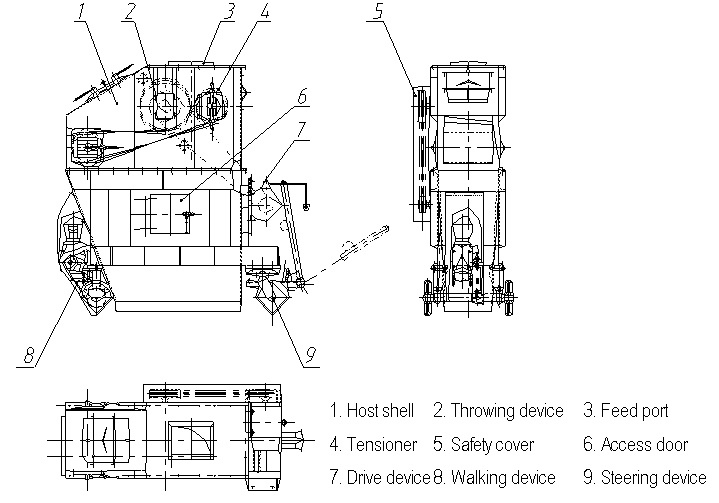

●The main structure of the throwing machine:

Including host shell, pallet, steering wheel, collecting hopper, manhole door, pulling arm, throwing device, driving device, tensioning device, walking mechanism, safety cover, switch device, electric control device, etc.

The throwing device includes the No. 1 tensioning drum, the No. 2 tensioning drum and the driving pinch roller. The No. 1 tensioning drum, the No. 2 tensioning drum and the driving pinch wheel are wound with a throwing belt. device is connected.

The main shaft of the No. 1 tensioning roller is installed on the horizontal chute of the main frame to form a sliding fit, and the tensioning degree is adjusted by the screw tensioning device.

The main shaft that drives the pinch pulley is installed on the No. 1 vertical chute of the main frame to form a sliding fit, and the tensioning degree is adjusted by the screw tensioning device.

The main shaft of the No. 2 tensioning drum is installed on the No. 2 vertical chute of the main frame to form a sliding fit, and the tensioning degree is adjusted by the screw tensioning device.

The top of the mainframe casing is provided with a top observation door, and the rear side is provided with a rear observation door.

This machine is provided with a movable steering running mechanism, which requires a light and compact structure to reduce power consumption and be flexible in use. In order to reduce the labor intensity of workers when moving the throwing machine, the machine is equipped with an automatic traveling mechanism and is equipped with a brake.

The annular tape used in this machine is a wear-resistant and strong throwing belt. The material is added from the middle of the driving pinch roller. The annular belt moves at a high speed through the tension roller and the driving pinch wheel. Due to inertia, the material is thrown into the container, such as a container. , incinerators, etc.

In order to achieve the purpose of adjusting the throwing distance and angle, two tensioning rollers and one driving pinch roller on the annular tape can realize the adjustment function.

In order to prevent the material from spilling during the conveying process, a collecting hopper is set under the conveying belt, and a clearing door is set; the collecting hopper can also be connected with the storage conveyor to recover the scattered materials.

Schematic diagram of the overall structure of the throwing machine

Video

WORKSHOP

AFTER-SALES COMMITMENT

1.Product Quality Commitment:

1.1The quality of all manufactured products complies with international, national, and industry standards, as well as our company's internal standards.

1.2In the event of any loss caused by product quality issues, our company will fully assume the responsibility as determined by the relevant authorities.

2.After-Sales Service Commitment:

2.1 Company Service:

2.1.1 **Competitive Supply Price:** We will supply products to your company at the most favorable prices to maximize your profits. Additionally, we can customize product specifications based on your specific needs.

2.1.2 **Efficient Supply Service:** To ensure timely and accurate delivery, we continuously optimize our production planning and logistics distribution processes.

2.1.3 **Product Follow-Up and Supply:** Our customer service department will be responsible for product follow-up and supply, ensuring that products are delivered on time, with high quality and in the required quantities.

2.1.4 **Convenient Customer Service:**

-**Accessibility:** We provide multiple channels for communication, including telephone, fax, and email. Our professional team is available to assist you at any time.

-**Efficiency:** Our full-time staff will promptly respond to customer inquiries, demonstrating our commitment to professionalism and efficiency.

-**Technical Support:** Leveraging modern electronic communication technology, we offer comprehensive and efficient services through various media.

2.1.5 **Regular Communication:** Our senior management will maintain regular and irregular communication with your responsible person to enhance cooperation. This will not only promote the sales of your products through user satisfaction but also increase your brand awareness by expanding your market share.

2.1.6 **Product Monitoring and Cost Reduction:** We will collaborate with you to regularly monitor products in real-time, extend their life cycle, and reduce production costs.

2.2 Service to Your Users:

2.2.1 **Market Research and Product Tracking:** We will conduct in-depth market research and product tracking to facilitate continuous improvement and new product development.

2.2.2 **Regular Follow-Up Visits:** Our team will provide regular follow-up visits to ensure the highest level of professional care is delivered directly to the users.

2.2.3 **Operational Guidance:** Our service department is available to provide users with guidance and training on the use and maintenance of our products.

2.2.4 **Prompt Problem Resolution:** Users can contact our company at any time if they have any questions or issues regarding the products. We will address these concerns promptly.

2.2.5 **Training on Usage Knowledge:** We will regularly conduct training sessions for relevant personnel to enhance their knowledge and skills in using our products.

Key Word : Throwing machine

Get a Free Quote

To: YIYUN MEC.&ELEC.