Categories

MC serial general En-masse conveyor

MC serial general En-masse conveyor

The company's main products are: En - masse conveyor, bucket elevator, screw conveyor, belt conveyor, slat conveyor, FU drag chain conveyor, crusher and all kinds of manual, electric, pneumatic gate & valves, slag silo and so on.

PRODUCT DESCRIPTION

●Technical parameters sheet of MC serial general En-masse conveyor

Machine size | MC16 | MC20 | MC25 | MC32 | MC40 | |||||||||||||||

Vertical casing width B(mm) | 160 | 200 | 250 | 320 | 400 | |||||||||||||||

Vertical casing height h(mm) | 120 | 130 | 160 | 200 | 250 | |||||||||||||||

Capacity of the conveyor Q (t/m3) | ||||||||||||||||||||

Speed of the scraper V m/s | 0.16 | 11 | 15 | 23 | 35 | 56 | ||||||||||||||

0.20 | 14 | 19 | 29 | 46 | 70 | |||||||||||||||

0.25 | 17 | 23 | 36 | 58 | 88 | |||||||||||||||

0.32 | 22 | 30 | 46 | 74 | 112 | |||||||||||||||

Maximum verticallifting height H。(m) | ||||||||||||||||||||

Machine size | bottom horizontal casing length m | The scraper | the volume weight of the materials to be conveyed | |||||||||||||||||

the pitch of chain | Type | Allowable load kg | 0.2 | 0.5 | 0.8 | 1.0 | 1.2 | 1.5 | 1.8 | |||||||||||

MC16 | 5 | 100 | DV1 | 1500 | 30* | 30* | 25 | 19 | 15 | 11 | 8 | |||||||||

1700 | 30* | 30* | 30 | 24 | 19 | 14 | 10 | |||||||||||||

DO | 1500 | 30* | 30* | 24 | 19 | 15 | 10 | 7 | ||||||||||||

1700 | 30* | 30* | 29 | 23 | 18 | 14 | 10 | |||||||||||||

GV1 | 1500 | 30* | 30* | 24 | 19 | 15 | 10 | 7 | ||||||||||||

1700 | 30* | 30* | 29 | 23 | 18 | 13 | 10 | |||||||||||||

GO | 1500 | 30* | 30* | 23 | 18 | 14 | 10 | 7 | ||||||||||||

1700 | 30* | 30* | 28 | 22 | 18 | 13 | 10 | |||||||||||||

MC20 | 5 | 125 | DV1 | 2300 | 30* | 30* | 30 | 24 | 19 | 14 | 10 | |||||||||

2600 | 30* | 30* | 30* | 28 | 23 | 17 | 13 | |||||||||||||

DO | 2300 | 30* | 30* | 29 | 23 | 19 | 14 | 10 | ||||||||||||

2600 | 30* | 30* | 30* | 28 | 22 | 17 | 13 | |||||||||||||

GV1 | 2300 | 30* | 30* | 28 | 22 | 18 | 13 | 10 | ||||||||||||

2600 | 30* | 30* | 30* | 26 | 21 | 14 | 12 | |||||||||||||

GO | 2300 | 30* | 30* | 27 | 21 | 17 | 13 | 9 | ||||||||||||

2600 | 30* | 30* | 30* | 25 | 21 | 14 | 12 | |||||||||||||

MC25 | 5 | 160 | DV1 | 3100 | 30* | 30* | 24 | 18 | 14 | 10 | 7 | |||||||||

3500 | 30* | 30* | 28 | 22 | 17 | 13 | 9 | |||||||||||||

DO | 3100 | 30* | 30* | 23 | 18 | 14 | 10 | 7 | ||||||||||||

3500 | 30* | 30* | 27 | 21 | 17 | 12 | 9 | |||||||||||||

GV1 | 3100 | 30* | 30* | 23 | 18 | 14 | 10 | 7 | ||||||||||||

3500 | 30* | 30* | 27 | 21 | 17 | 13 | 9 | |||||||||||||

GO | 3100 | 30* | 30* | 22 | 17 | 14 | 10 | 7 | ||||||||||||

3500 | 30* | 30* | 27 | 21 | 17 | 12 | 9 | |||||||||||||

MC32 | 6 | 200 | BO | 2900*2 | 30* | 30* | 21 | 16 | 12 | 9 | 6 | |||||||||

3300*2 | 30* | 30* | 25 | 20 | 16 | 11 | 8 | |||||||||||||

BO4 | 2900*2 | 30* | 30* | 20 | 16 | 12 | 9 | 6 | ||||||||||||

3300*2 | 30* | 30* | 25 | 19 | 15 | 11 | 8 | |||||||||||||

The MC type En-masse conveyor is a continuous conveying device used for transporting bulk materials, widely applied in industries such as metallurgy, building materials, chemical engineering, power generation, and coal. It moves materials through a closed rectangular casing using a moving scraper chain, enabling horizontal, inclined, or vertical conveying. The MC type en masse conveyor is especially suitable for high-angle (30° to 90°) and vertical conveying, efficiently transferring materials from lower to higher levels.

Note: 1.The values marked with * shouldn't exceeded.

2.The values marked with ** are not considered conveyor efficiency.

3.The values in table are calculated according to the following conditions.

(1) The conveyor is vertical(α=90°); the head is A type(without return idler); the inlet section is B type(double side inlet).

(2) Material:: the internal friction angle is φ1=45°f=1;the outer friction angle is φ1=31° f1=0.6; χ=1,η=0.59.

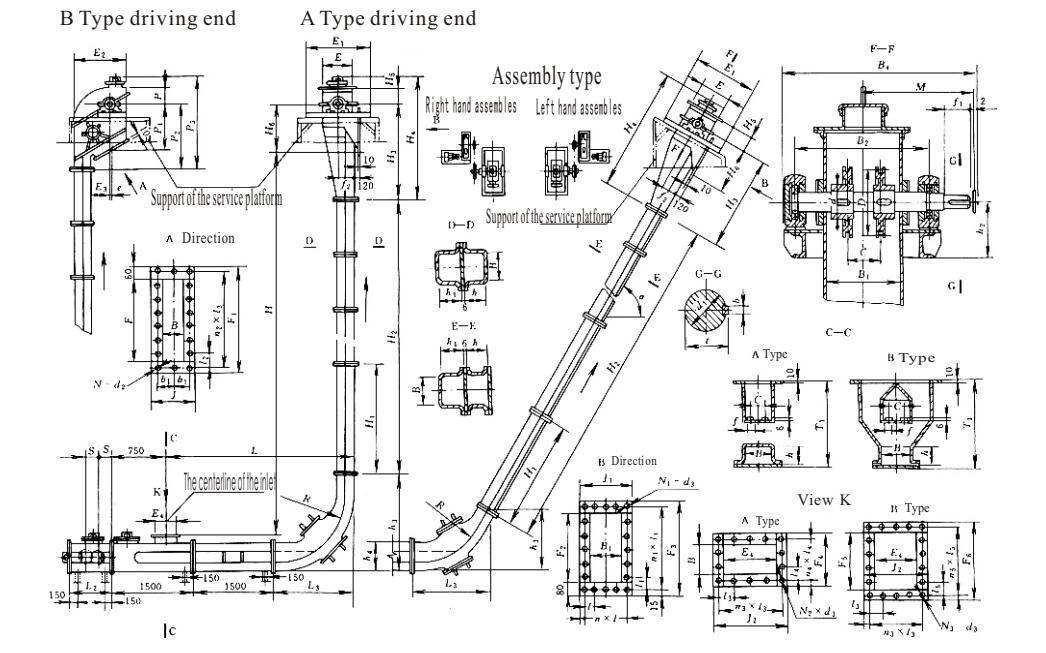

●Dimensions of MC general En-masse conveyor

Note: 1.All of the chain scraper adopt outgoing arrangement ,the chain scraper are not shown in the drawing.

2.The driving end ,vertical casing.bend casing and inlet section are A and B type.. when the B type driving end is selected, it must match the A type vertical casing and bend casing; when the A type driving end is selected, it must match the B type vertical casing and bend casing; the inlet section will be arbitrary selection.The type of selection as shown in the above drawing.

3.When the B type driving end is selected, the DO and GO type chain scraper can't be used.

Video

WORKSHOP

AFTER-SALES COMMITMENT

1.Product Quality Commitment:

1.1The quality of all manufactured products complies with international, national, and industry standards, as well as our company's internal standards.

1.2In the event of any loss caused by product quality issues, our company will fully assume the responsibility as determined by the relevant authorities.

2.After-Sales Service Commitment:

2.1 Company Service:

2.1.1 **Competitive Supply Price:** We will supply products to your company at the most favorable prices to maximize your profits. Additionally, we can customize product specifications based on your specific needs.

2.1.2 **Efficient Supply Service:** To ensure timely and accurate delivery, we continuously optimize our production planning and logistics distribution processes.

2.1.3 **Product Follow-Up and Supply:** Our customer service department will be responsible for product follow-up and supply, ensuring that products are delivered on time, with high quality and in the required quantities.

2.1.4 **Convenient Customer Service:**

-**Accessibility:** We provide multiple channels for communication, including telephone, fax, and email. Our professional team is available to assist you at any time.

-**Efficiency:** Our full-time staff will promptly respond to customer inquiries, demonstrating our commitment to professionalism and efficiency.

-**Technical Support:** Leveraging modern electronic communication technology, we offer comprehensive and efficient services through various media.

2.1.5 **Regular Communication:** Our senior management will maintain regular and irregular communication with your responsible person to enhance cooperation. This will not only promote the sales of your products through user satisfaction but also increase your brand awareness by expanding your market share.

2.1.6 **Product Monitoring and Cost Reduction:** We will collaborate with you to regularly monitor products in real-time, extend their life cycle, and reduce production costs.

2.2 Service to Your Users:

2.2.1 **Market Research and Product Tracking:** We will conduct in-depth market research and product tracking to facilitate continuous improvement and new product development.

2.2.2 **Regular Follow-Up Visits:** Our team will provide regular follow-up visits to ensure the highest level of professional care is delivered directly to the users.

2.2.3 **Operational Guidance:** Our service department is available to provide users with guidance and training on the use and maintenance of our products.

2.2.4 **Prompt Problem Resolution:** Users can contact our company at any time if they have any questions or issues regarding the products. We will address these concerns promptly.

2.2.5 **Training on Usage Knowledge:** We will regularly conduct training sessions for relevant personnel to enhance their knowledge and skills in using our products.

Key Word : MC serial general En-masse conveyor

Get a Free Quote

To: YIYUN MEC.&ELEC.