Slat Conveyor: Characteristics, Core Advantages and Applications

Author :

As an efficient and stable material handling equipment, the characteristics and advantages of the slat conveyor are closely centered around the core requirements of“strong adaptability, high reliability, and flexible operation,” and it is widely applicable to complex conveying scenarios in various industries. The following is a detailed analysis from two aspects: core characteristics and core advantages, with application scenarios illustrating its value:

Ⅰ Core Characteristics of slat conveyors

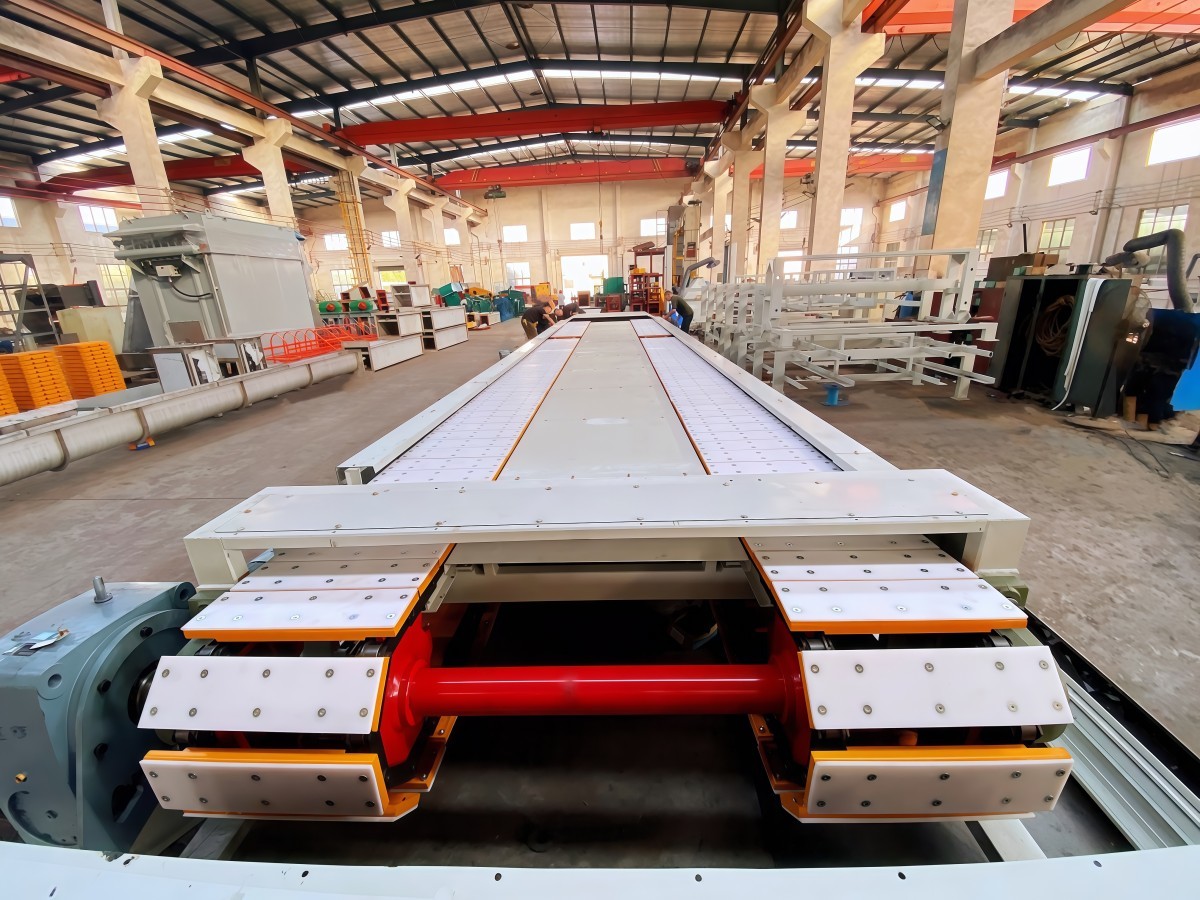

The structural design of the slat conveyor (with chains as the traction and plates as the load-bearing elements) determines its unique properties, which are distinct from those of belt conveyors and roller conveyors. The main features are as follows:

1. High Load-Bearing Capacity, Suitable for Various Material Forms

The core load-bearing components are metal (or high-strength plastic) plates, typically 3-10mm thick, capable of withstanding significant material weight and impact loads.

• It can convey materials in block,granular,and powdered forms (such as ore,coal,grain) as well as packaged items (such as cardboard boxes, pallets, components).

• It allows materials with certain hardness or sharp edges (such as metal castings, stone materials) without worrying about damage like belt conveyors that may be scratched by materials.

2. Flexible Conveying Paths, Adaptable to Complex Layouts

Based on the transmission characteristics of the chains, slat conveyors can achieve various spatial layouts, breaking through the limitations of “single horizontal/tilted” configurations:

• They support horizontal conveying, inclined conveying (with a maximum incline of up to 30°, and some special designs can reach 45°), and vertical lifting (with dedicated plate structures).

• They can be designed as corner types (90°/180°bends) or looped, meeting the “cross-regional,around-equipment” conveying needs in workshops (such as the flow of parts in automotive production lines).

3. Wide Environmental Adaptability, Resistant to Harsh Conditions

The plates and chains are often made of stainless steel, carbon steel (with galvanizing/spraying), or engineering plastics (such as PP,PE), combined with sealed drive units, enabling them to withstand various extreme environments:

• High-temperature environments: Metal plates can withstand temperatures of 150-300°C (such as conveying high-temperature materials in the chemical industry, cooling after baking in the food industry).

• Humid/corrosive environments: Stainless steel materials can resist acid and alkali corrosion (such as conveying parts in electroplating workshops, sludge in wastewater treatment plants).

• Dusty environments: The closed plate design can reduce material spillage and prevent dust diffusion (such as conveying cement and lime in the building materials industry).

4. Stable Operation, Low Failure Rate

• Simple transmission structure: Driven by chain wheels meshing with chains, it avoids common issues like belt slipping and roller jamming, with a transmission efficiency of over 95%.

• Easy maintenance of wear parts: Chains, plates, and chain wheels are highly standardized, and replacement does not require disassembling the entire equipment, keeping maintenance costs low.

• Overload protection can be configured: When materials jam or the load exceeds the standard, the drive unit’s overload protection (such as a torque limiter) will automatically shut down to prevent equipment damage.

5. Controllable Conveying Speed, Adaptable to Process Requirements

Typically driven by variable - frequency motors, the conveying speed can be flexibly adjusted according to the production rhythm (usually ranging from 0.5-5m/min):

• Low-speed scenarios: Such as sorting and labeling processes in the food industry (where precise material positioning is required).

• High-speed scenarios: Such as express sorting lines in the logistics industry (where high conveying efficiency is needed).

Ⅱ Core Advantages of slat conveyors (Compared with Other Conveyors)

Compared with belt conveyors, slat conveyors have more prominent advantages in specific scenarios, as shown in the following comparison:

Comparison Dimension | slat conveyor | Belt Conveyor |

Material Adaptability | Strong (capable of handling blocky, sharp, and high-temperature materials) | Weak (easily scratched by sharp materials, not heat-resistant) |

Conveying Incline | Large (up to 30°-45°) | Small (up to 15°-20°, prone to slipping) |

Environmental Tolerance | High (resistant to high and low temperatures, corrosion, and dust) | Low (belts are prone to aging, moisture absorption, and oil contamination) |

Maintenance Cost | Low (standardized wear parts, easy replacement) | High (belt replacement requires complete disassembly, high cost) |

Positioning Accuracy | High (good synchronization of plates, precise positioning) | Low (belts are prone to stretching, large positioning errors) |

From the comparison, it is evident that when the conveying scenario involves “heavy loads, complex-shaped materials, harsh environments, and large inclines,” the advantages of slat conveyors far outweigh those of other types of equipment.

Ⅲ Advantages in Typical Application Scenarios

1. Heavy Industry (Metallurgy, Mining)

• Requirement: Convey heavy loads (such as ore,steel slag) with individual pieces weighing over 50kg and high hardness materials.

• Advantage: Metal plates are impact-resistant and wear - resistant, eliminating the risk of material scratching the equipment, and can achieve long - distance continuous conveying (up to over 100m).

2. Food Processing Industry

• Requirement: Convey food raw materials (such as meat, fruits, and vegetables) or finished products, meeting hygiene standards (washable) and adapting to high and low - temperature environments (such as freezing at -20℃ and baking at 200℃ ).

• Advantage: Stainless steel plates are detachable for washing and heat - resistant, while plastic plates are lightweight and odorless, meeting food - grade certification.

3. Logistics and Warehousing

• Requirement: Convey packaged goods (such as cardboard boxes, pallets), requiring multi-path conveying including “horizontal+turning+lifting.”

• Advantage: The looped plate design enables continuous conveying,with compact turning structures (minimum turning radius can reach 500mm), saving workshop space.

4. Chemical and Environmental Protection Fields

• Requirement: Convey materials soaked in acid and alkali solutions, sludge, or high-temperature waste slag.

• Advantage: Corrosion-resistant materials (such as 316L stainless steel) prevent equipment rusting, and sealed plates avoid material leakage and environmental pollution.

In summary, the core value of plate conveyors lies in “adapting to complex demands with structural advantages.” Whether it is the form of materials, conveying environment, or layout requirements, their flexibility and reliability can meet the personalized conveying needs of multiple industries. They are the preferred equipment for “heavy load and high stability” conveying scenarios in industrial production.

Slat Conveyor,complex conveying scenarios,material handling,industrial solutions

Get a Free Quote

We sincerely welcome you to write to us, call us to inquire about our business, visit us, inspect us, buy us and adopt us. You have any questions you can write to call, you can also leave a message on this site, the site administrator will do our best to provide you with the most efficient service.