Categories

Heavy-Duty Slat Conveyor

Heavy-Duty Slat Conveyor

The company's main products are: En - masse conveyor, bucket elevator, screw conveyor, belt conveyor, slat conveyor, FU drag chain conveyor, crusher and all kinds of manual, electric, pneumatic gate & valves, slag silo and so on.

Category :

Slat conveyor

Heavy-Duty Flake Feeder

Heavy-Duty Slat Conveyor

PRODUCT DESCRIPTION

Heavy-Duty Slat Conveyor

The heavy-duty slat conveyor is a high-strength continuous conveying equipment designed for ultra-heavy, high-impact, and harsh working conditions. Its core positioning is "ultimate load-bearing capacity and extreme tolerance," capable of handling materials weighing over 200kg or even several tons per piece, as well as severe scenarios such as strong impacts (material height > 500mm), high temperatures (>500℃), and high wear. It is an "irreplaceable conveying core" in heavy industrial production.

Core Design Positioning: Ultimate Load-Bearing Capacity and Extreme Tolerance

The design logic of the heavy-duty slat conveyor prioritizes "strength first"—by reinforcing the entire chain (from the board to the drive), it breaks through the upper limit of the load-bearing capacity of light and medium equipment, addressing the pain point of "unstable transportation of ultra-heavy materials." Its typical application scenarios require meeting the following criteria: single material weight ≥ 200kg (even up to more than 10 tons), unit length load capacity ≥ 150kg/m, material falling height often exceeding 500mm (such as direct feeding from a high-altitude silo), or accompanied by extreme conditions such as high temperatures (e.g., red-hot steel billets) and strong wear (e.g., large ore blocks).

Key Structure and Parameters: Full Link Reinforcement

Scale Board (Conveying Panel)

• Material: High-strength wear-resistant steel or alloy cast steel is selected (such as NM400/NM500 wear-resistant plate, ZG35CrMo cast steel), with a thickness of ≥ 10mm (up to 15-20mm in extreme fields), a tensile strength of ≥ 800MPa, and the ability to withstand severe impacts without deformation or fracture.

• Specification: The width is usually 1200-3000mm, and the length of a single board is 1000-2000mm. High-strength bolts are used for rigid connections between boards (instead of the overlap used in light/medium equipment), with a gap of ≤ 5mm (to prevent material leakage and enhance overall rigidity). The surface is reinforced with dense ribs (thickness 8-12mm, spacing 100-200mm), and in some scenarios, wear-resistant lining plates (such as high-chromium cast iron) are also welded to further enhance wear resistance.

Chain and Drive System

• Chain: Special heavy-duty chains are used (such as plate chains and forged chains), with a pitch of ≥ 200mm (commonly 250-400mm), a chain plate thickness of 10-15mm, and a pin shaft diameter of ≥ 20mm (made of high alloy structural steel such as 40CrNiMoA, quenched and tempered + surface quenched, with a hardness of HRC45-50). The system is mostly driven by multiple chains (2-4 parallel), with force evenly distributed through synchronous shafts, and the rated tension of a single chain is ≥ 50kN.

• Drive: The motor power ranges from 15-75kW (customized according to the conveying length and load), paired with a high-power hard-tooth reducer (reduction ratio 50-100), with an output torque of ≥ 1000N·m. The operating speed is extremely low (0.3-0.8m/min), prioritizing stability under heavy loads. Standard overload protection devices (such as hydraulic couplings and torque limiters) are equipped to prevent damage to chains or motors caused by overload.

Rack and Support

• Rack: Made of large H-beam steel (200×200-400×400mm) or box beam welding, with a wall thickness of 8-15mm and a single-meter weight of ≥ 50kg. The entire structure is annealed to eliminate welding stress. Installation requires fixing on a reinforced concrete deep foundation (foundation thickness ≥ 300mm, embedded steel plate thickness ≥ 20mm), and seismic design is also required in some scenarios (such as mines and metallurgical workshops).Track and Guidance

• Track: Made of integral cast steel or wear-resistant steel rails (such as QU100 crane rails), fixed on both sides of the frame, with a support surface width of ≥ 50mm for the chain. Equipped with precision guidance devices (such as lateral guide wheels) to prevent eccentric wear caused by chain deviation.

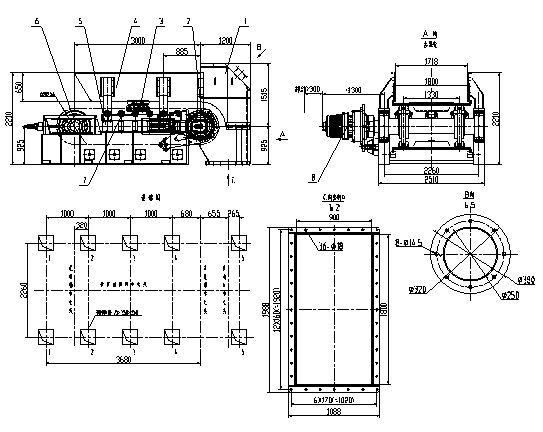

●Layout of heavy-duty slat conveyor:

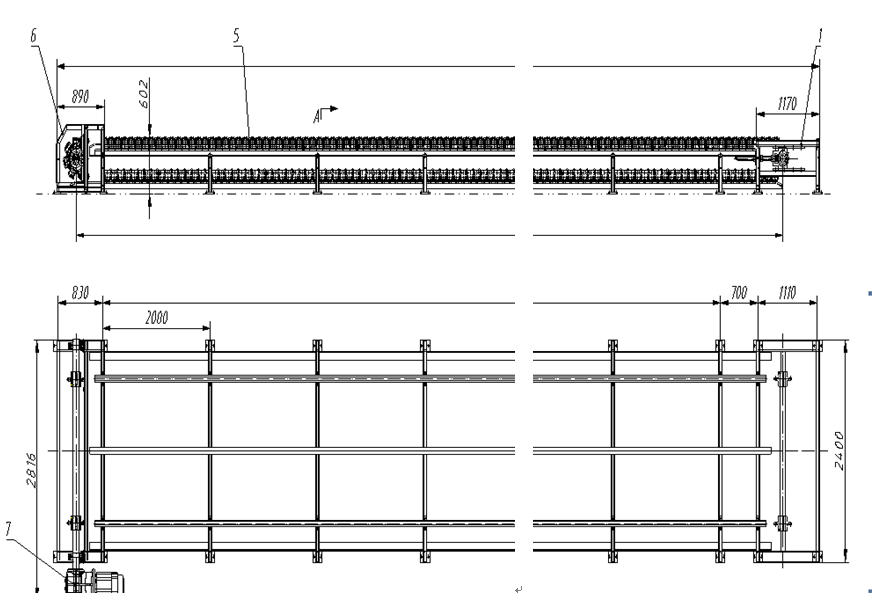

●Flat chain conveyor layout:

The following table lists five types of light series feeders, the maximum feeding volume can reach 845m3/h, and the main technical parameters are:

●Technical parameters sheet of QBG type Light-duty slat feeder

|

Machine size |

Casing width |

Head to tail wheel center distance(mm) |

Speed of feeder |

Rated capacity (m3/h) |

The largest feed particle size(mm) |

| QBG500-2 |

500 |

2000 |

0.05-0.4 |

7-88 |

180 |

| QBG500-3 |

3000 |

||||

| QBG500-4.5 |

4500 |

||||

| QBG500-6 |

6000 |

||||

| QBG500-9 |

9000 |

||||

| QBG500-12 |

12000 |

||||

| QBG500-15 |

15000 |

||||

| QBG630-3 |

30 |

3000 |

0.04-0.4 |

11-175 |

200 |

| QBG630-4.5 |

4500 |

||||

| QBG630-6 |

6000 |

||||

| QBG630-9 |

9000 |

||||

| QBG630-12 |

12000 |

||||

| QBG630-15 |

15000 |

||||

| QBG800-3 |

800 |

3000 |

0.04-0.4 |

19-308 |

350 |

| QBG800-4.5 |

4500 |

||||

| QBG800-6 |

6000 |

||||

| QBG800-9 |

9000 |

||||

| QBG800-12 |

12000 |

||||

| QBG800-15 |

15000 |

||||

| QBG800-18 |

18000 |

||||

| QBG1000-3 |

1000 |

3000 |

0.03-0.4 |

25-507 |

460 |

| QBG1000-4.5 |

4500 |

||||

| QBG1000-6 |

6000 |

||||

| QBG1000-9 |

9000 |

||||

| QBG1000-12 |

12000 |

||||

| QBG1000-15 |

15000 |

||||

| QBG1000-18 |

18000 |

||||

| QBG1250-3 |

1250 |

3000 |

0.03-0.4 |

40-845 |

600 |

| QBG1250-4.5 |

4500 |

||||

| QBG1250-6 |

6000 |

||||

| QBG1250-9 |

9000 |

||||

| QBG1250-12 |

12000 |

||||

| QBG1250-15 |

15000 |

||||

| QBG1250-18 |

18000 |

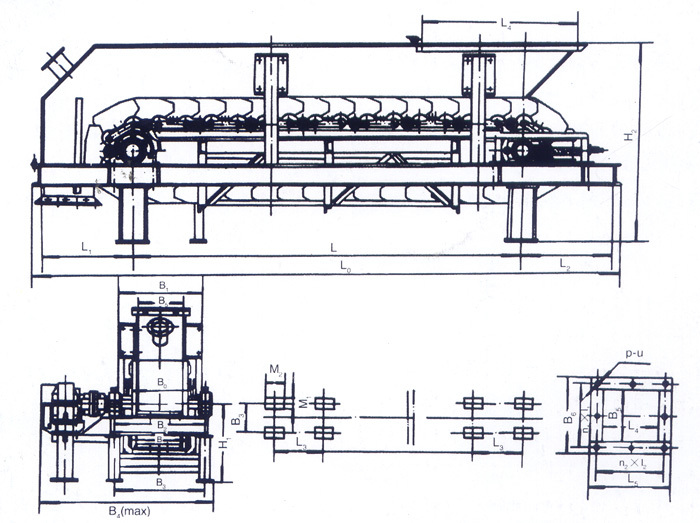

●Dimensions of QBG type Light-duty slat feeder

Video

WORKSHOP

AFTER-SALES COMMITMENT

1.Product Quality Commitment:

1.1The quality of all manufactured products complies with international, national, and industry standards, as well as our company's internal standards.

1.2In the event of any loss caused by product quality issues, our company will fully assume the responsibility as determined by the relevant authorities.

2.After-Sales Service Commitment:

2.1 Company Service:

2.1.1 **Competitive Supply Price:** We will supply products to your company at the most favorable prices to maximize your profits. Additionally, we can customize product specifications based on your specific needs.

2.1.2 **Efficient Supply Service:** To ensure timely and accurate delivery, we continuously optimize our production planning and logistics distribution processes.

2.1.3 **Product Follow-Up and Supply:** Our customer service department will be responsible for product follow-up and supply, ensuring that products are delivered on time, with high quality and in the required quantities.

2.1.4 **Convenient Customer Service:**

-**Accessibility:** We provide multiple channels for communication, including telephone, fax, and email. Our professional team is available to assist you at any time.

-**Efficiency:** Our full-time staff will promptly respond to customer inquiries, demonstrating our commitment to professionalism and efficiency.

-**Technical Support:** Leveraging modern electronic communication technology, we offer comprehensive and efficient services through various media.

2.1.5 **Regular Communication:** Our senior management will maintain regular and irregular communication with your responsible person to enhance cooperation. This will not only promote the sales of your products through user satisfaction but also increase your brand awareness by expanding your market share.

2.1.6 **Product Monitoring and Cost Reduction:** We will collaborate with you to regularly monitor products in real-time, extend their life cycle, and reduce production costs.

2.2 Service to Your Users:

2.2.1 **Market Research and Product Tracking:** We will conduct in-depth market research and product tracking to facilitate continuous improvement and new product development.

2.2.2 **Regular Follow-Up Visits:** Our team will provide regular follow-up visits to ensure the highest level of professional care is delivered directly to the users.

2.2.3 **Operational Guidance:** Our service department is available to provide users with guidance and training on the use and maintenance of our products.

2.2.4 **Prompt Problem Resolution:** Users can contact our company at any time if they have any questions or issues regarding the products. We will address these concerns promptly.

2.2.5 **Training on Usage Knowledge:** We will regularly conduct training sessions for relevant personnel to enhance their knowledge and skills in using our products.

Key Word : Heavy-Duty Slat Conveyor

Get a Free Quote

To: YIYUN MEC.&ELEC.