Application of En-Masse Conveyor in Port Terminals

Author :

Key Scenarios and Advantages in Bulk Material Handling

The En-masse conveyor is a fully enclosed, continuous conveying device. Its main components are the trough, scraper chain, and drive unit. It conveys bulk materials by the traction achieved through the continuous movement of the scraper chain inside an enclosed trough.

It can handle horizontal, inclined—with a maximum inclination of ≤30°—and vertical configurations. It has a wide range of applications for bulk materials, including coal, ore, grain, and chemical powders. The range for capacity is wide at 1-1000m³/h. Its most important feature is the full enclosure, which enables it to eliminate dust and pollution. Besides, it possesses great spatial adaptability and can be mounted flexibly in complex layouts.

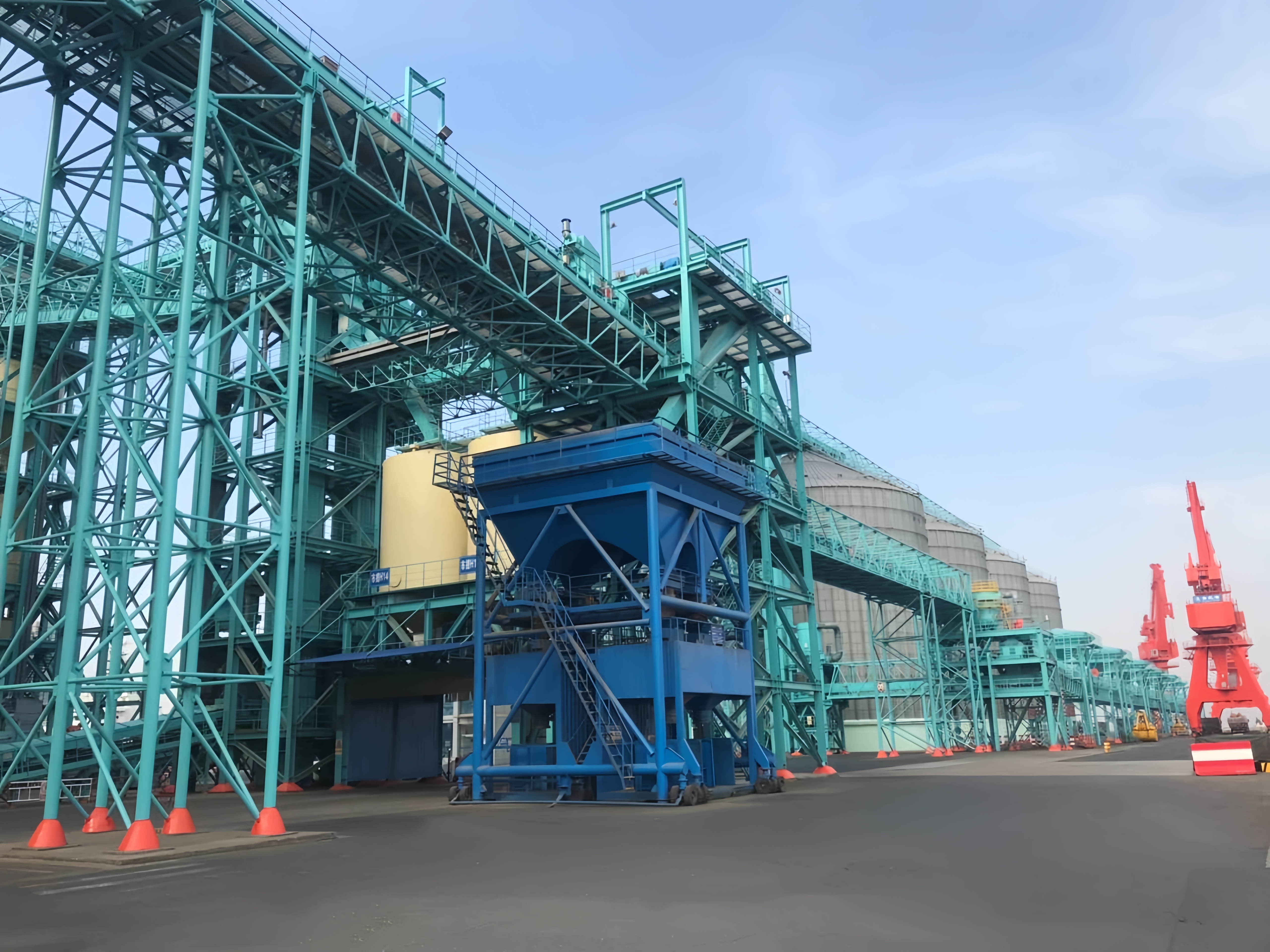

In port terminals, the En-masse conveyor is specifically utilized for the enclosed, continuous, and efficient transportation of bulk materials. It is one of the key devices that links the entire process of unloading ships to storage and then loading onto ships or trucks.

Core Application Scenarios

Its application runs through the key links of port bulk material handling, mainly focusing on three types of scenarios:

• Transshipment after unloading ships: It receives materials such as coal, iron ore, and grain unloaded by ship unloaders (e.g., grab unloaders, screw unloaders) and offers them from the quayside to the rear storage bins or stockyards without allowing material accumulation.

• Material allocation in storage areas: It transfers materials between storage bins or raw bins to pre-treatment equipment such as crushers and screens for further processing, classified storage, and flexible allocation of different materials.

• Conveying before loading ships/trucks: It completes the bulk transfer from storage bins to ship loaders or truck loading buildings for export or land transport transshipment, for instance, corn and soybean loading for grain ports or coal loading for train transshipment in coal ports.

Core Advantages for Ports

Compared to traditional equipment like belt conveyors, it has three main advantages in port environments:

• Environmental Protection: The totally enclosed trough design ensures absolutely no dust emissions during cargo handling, fully complying with modern standards of environmental protection in the ports. In addition, the conveying trough keeps the material protected from rain, snow, and sea mist.

• Spatial Adaptability: Horizontal and inclined conveying—up to an inclination angle of about 30°—is also possible considering vertical conveying. This makes instant flexibility concerning site restrictions an optimal choice for piers concerning underground and overhead space.

• Smooth Operation: Since the scraper chain always runs matched into the trough, the traction force stays constantly undisturbed. It is less affected by port environmental factors, such as turbulence from wind and vibration, and is thus ideally suited to stable high-load continuous operation.

Application Precautions

To ensure the long-term reliable operation of the system, two points need to be focused on:

Material adaptation: Selecting either T-type or U-type scrapers and troughs according to the materials' sizes finely for coal, lumps of ore and moisture—for instance, wet and sticky materials—to avoid blockages or excessive wear.

Maintenance and protection: periodical checking of the scraper chain wear and the operating condition of the drive unit; in the case of a highly saline fog environment at ports, enhanced rust and corrosion protection measures will be taken to further ensure longevity.

En-masse conveyor,Bulk Material Handling,Port Terminals

Get a Free Quote

We sincerely welcome you to write to us, call us to inquire about our business, visit us, inspect us, buy us and adopt us. You have any questions you can write to call, you can also leave a message on this site, the site administrator will do our best to provide you with the most efficient service.